How Ensign Energy Services Incand Nabors Industries ltd. can Save You Time, Stress, and Money.

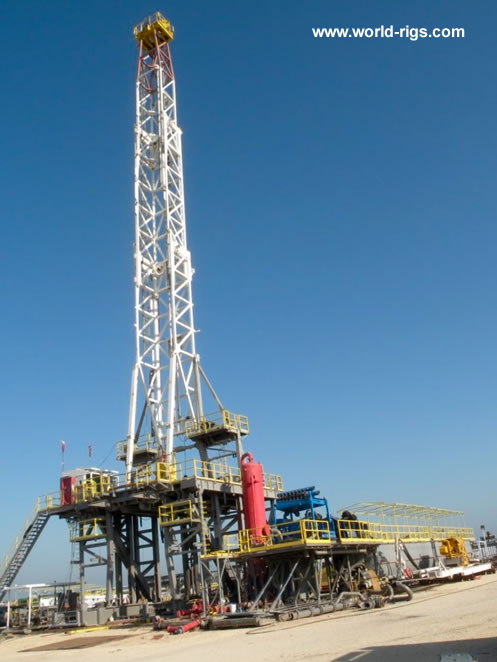

CP-300 Jackup - Drilling Rigs for Sale - Oilfield Equipment - Offshore Rigs and Vessels

New Jackup Rigs, Offshore Rig Brokers, Offshore Rigs Dealers, Offshore Rigs Sellers, Jackup Rigs available

Some Of 90% Off Sale On Offshore Drilling Rigs? - OilPrice.com

and time needed to develop a wooden platform to support all or a few of the offshore-type rig. Click Here For Additional Info was the Mr. Charlie, designed and constructed from scratch by Ocean Drilling and Exploration Co.(ODECO), headed by its developer and president,"Doc "Alden J. Laborde. The Mr. Charlie (Fig. 2)was a purpose-built submersible barge constructed specifically to drift on its lower hull to area and, in a series of flooding the stern down, wound up resting on the bottom to start drilling operations. Charlie went to its first area in June 1954, Life magazine wrote about the unique brand-new concept to check out for oil and gas offshore. The Mr. Charlie, ranked for 40-ft water depth, set the tone for how most Methods were integrated in the Gulf of Mexico (GOM). Typically, an innovator secured financiers, in this case Murphy Oil, and then discovered a customer with a contract to drill for, in this case Shell Oil, enabling bank loans to be obtained to build the unit. Rigs were installed on surplus The second world war ship hulls modified to drill in a floating position compared with sitting a submersible barge on the ocean bottom, as performed in the GOM. Oil business formed collaborations or continued individually, however MODUs were not designed and built by contract drilling business in California. Before the leasing of oil and gas rights in 1955, oil business cored with small rigs cantilevered over the side midship of old The second world war barges. These barges did not have well-control devices or the ability to run a casing program. They could just drill to a designated core depth with the understanding that if they drilled into any oil and/or gas sands, they would stop, set a cement plug, and take out of the core hole. Others followed rapidly, with all of them worried about the marine environment and technology to enable drilling in rough weather. In 1956, the CUSS 1 was developed from another The second world war barge. The unit, developed by the CUSS group(Continental, Union, Shell, and Superior Oil), was 260 ft long and had a 48-ft beam. The original designers had no examples or experiences to go by, so novelty and innovation were the course of the day: Torque converters on the drawworks were.